27 May 2022

Italy was one of the main exhibitors at APLF 2022 that took place for the first time in Dubai from March 30th to April 1st. The Italian Trade Agency, in collaboration with the Embassy of Italy in the UAE, the Consulate General in Dubai and ASSOMAC (the national association of Italian manufacturers of footwear, leather goods and tanning technologies), hosted no less than 49 companies.

“After a gap of three years since its last edition in Hong Kong in 2019, APLF finally made it happen,” says enthusiastically Alessandro Lamura, Deputy Trade Commissioner to the UAE.

Italy is the leading European manufacturer of tanning machines, footwear and leather goods with a turnover of Euros 440 million in 2021; the industry currently employs over 3,900 people across 235 enterprises and it exported around Euro 305 million worth of machinery last year globally, about 70% of the total turnover.

While Asia is definitely the main destination market for Italian manufacturers with Euro 90 million of machinery exported in 2021, accounting for 30% of the total country’s export for this sector, the UAE is gradually becoming an important trade hub for the leather sector.

Italy is the second largest global leather machinery supplier to the UAE. It increased its exports of machinery for tanning, footwear and leather products to the UAE by 80%, reinforcing the two countries strong trade partnership in the sector. This follows two years of steady consecutive growth of Italy’s market share with the UAE, with an increase to a quota of 35% in 2021 from 3% in 2019, showing how Italian advancements in technology for the manufacturing of leather is highly regarded in the UAE.

Commenting on Italy’s participation in APLF Dubai, Lamura said, “APLF Dubai is the opportunity to reinforce our strong relationship with the UAE and may be a stepping stone to the wider region and to Africa”.

During the three year hiatus due to the Covid pandemic, Italy’s leading companies in leather machinery did not stay idle. Instead, they made significant investments into innovation and technology that not only create better products, but also reduce the environmental impact of the tanning process.

Expertise, Industry 4.0, Sustainability

This is the Assomac’s new motto. Thanks to knowledge in tanning being passed down through generations, Italian tanners are leading the pack in terms of Industry 4.0 development.

“Industry 4.0 has a strong link with sustainability”, explains Assomac’s Managing Director, Roberto Vago.

“For example, analysing data to improve production or predicting machine maintenance contribute to reducing the impact of leather making on the environment”.

In recognition of an industry association initiative establishing an environmental program that makes its members accountable for their carbon footprints, the BOAA Environment Prize was given to The Green Label initiative of Assomac. Since 2018, the Green Label initiative sets industry standards for determining a company’s environmental impact as evidenced by their levels of consumption of energy, water, chemicals, among others. This initiative was led by the Assomac members themselves to demonstrate their concern for the environment and wanting to be able to determine the effect their operations have on planet earth.

One of the recipients of the Green Label is Brustia-Alfameccanica, a leading company in the Italian mechanical shoe industry. “All our machines are equipped with Green Label that certifies they are designed with energy saving features”, explains the company’s General Manager, Maria Vittoria Brustia, and newly appointed president of Assomac. Brustia-Alfameccanica’s highlight is RFID technology (Radiofrequency identification), an all-in-one solution which improve footwear production and quality control and allows better traceabiity. “Thanks to RFID technologies, the machine operator no longer needs to waste time programming the machine for the different types of footwear being processed. Each machine recognizes the model and automatically sets the required settings”, describes Brustia.

Assomac’s manufacturers are also pioneering a certification for circular economy that sets new sustainable standards for the manufacturing of the machines they produce.

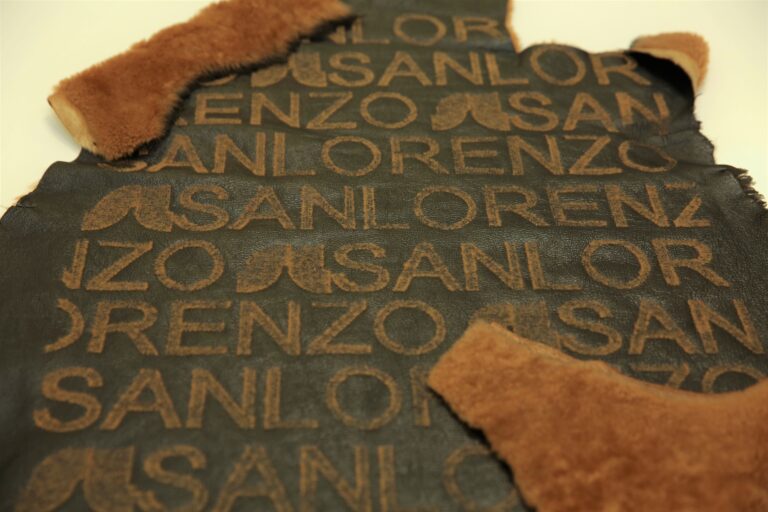

The show also featured two Italian Pavilions, presenting the country’s finest leather and leather products. Regione Campania hosted a total of 11 leather products companies, while UNIC, the country’s tanners’ association brought 24 exhibitors, of which one became the recipient of Best Fashion Leather Collection Award. Teampiel International, a tannery group located close to Florence, and known for its creativity. One of their latest creations is their interesting Needlepunch leather collection. This new technique involves taking loose hairs from the hide or yarns and needling them together to create patterns and motifs on the leather. This lends itself to many creative applications in fashion such as monogram designs. “This intriguing technique attracted a lot of interest during the show and we made many new contacts”, concludes Fabio Baldereschi, CEO and founder of the awarding company.

We bring leather, material and fashion businesses together: an opportunity to meet and greet face to face. We bring them from all parts of the world so that they can find fresh partners, discover new customers or suppliers and keep ahead of industry developments.

We organise a number of trade exhibitions which focus on fashion and lifestyle: sectors that are constantly in flux, so visitors and exhibitors alike need to be constantly aware both of the changes around them and those forecast for coming seasons.